Food safety

Food safety

At Megadyne, we understand the critical importance of food safety and take measures to continuously improve the hygiene and safety of your premises and end users. Our commitment to this concept means always looking for no compromises in food safety - a mission nearly impossible to achieve that still remains our goal.

What does food safety mean?

Food safety refers to the handling, processing, and storage of food in a manner that prevents contamination and potential poisoning. All responsible food producers prioritise the health and safety of their consumers and take measures to ensure their products are free from harmful contaminations and bacteria.

The importance of food safety

Adhering to food safety standards not only protects consumers from foodborne illnesses but also safeguards your business. Neglecting food safety norms can result in costly product recalls, damaging downtime, legal penalties, financial losses, and a tarnished reputation. Being a company devoted to the food safety concept means building a strong brand image of a responsible and caring leader in the industry.

AMMEGA approach to food safety

How does the choice of belt influence food safety?

Choosing the right quality timing belt can increase the level of food safety at your premises. For instance, blue belts are a standard choice because the colour itself doesn’t exist in food items and thus makes it easier to keep belts clean and improves the visual detection of foreign particles. While sanitising, you can recognise faster and more precisely what places need immediate cleaning and disinfection.

However, technological advancements have resulted in even more innovative solutions in the form of belts whose fragments can be identified by metal and X-ray detectors. This breakthrough significantly reduces the risk of contamination from broken belt elements.

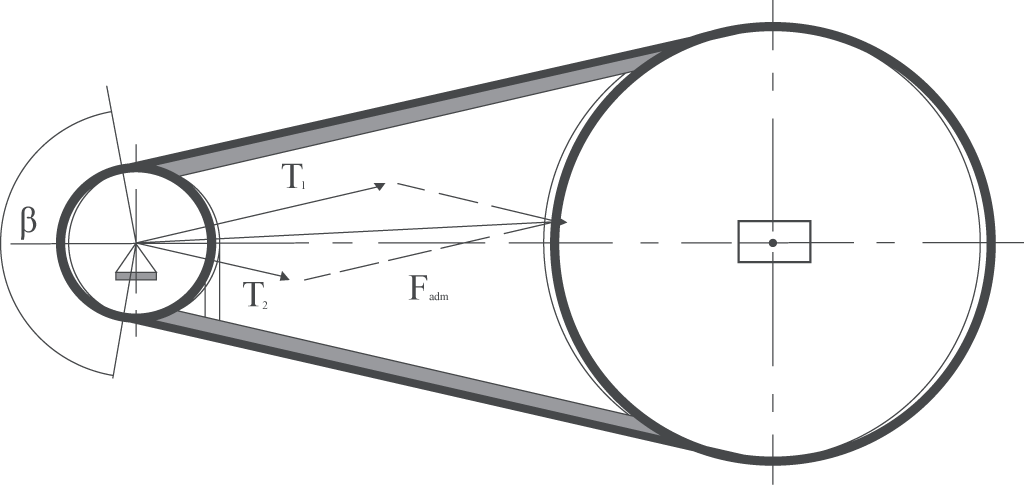

Some power transmission belts are easier to keep clean and sanitise than others because of their design. Their structure may reduce cross-contamination, counteract product build-up and demonstrate strong resistance to chemicals, humidity, and hydrolysis. For instance, a belt with sealed edges facilitates cleanability, prevents the absorption of fluids and oils and inhibits the growth of pathogenic microorganisms. The Megadyne XMD timing belt design eliminates the gaps between teeth and thus prevents foodstuffs from getting stuck in the construction. As a result, cleaning gets easier, and the risk of contamination is eliminated.

The durability of the power transmission belt is of importance, too. Belts can develop cracks due to extensive use or contact with sharp objects like knives. Food particles get into these grooves and cavities, creating a breeding ground for bacteria and food poisoning. Consequently, it is better to invest in durable solutions in which such problems do not occur.

As you may see, choosing the belt wisely influences your customers’ health and secures your company against costly product recalls and damage to reputation. With professional solutions offered by Megadyne and other members of the AMMEGA Group, you establish your position of a thoughtful leader and show care for your clients’ welfare.

Products

Megadyne is a proud member of the AMMEGA Group. Combining the strengths of all brands within the family, we take care of your food safety needs at the highest level. All our belts comply with worldwide food contact and safety standards such as the American FDA and the European USDA and EHEDG. Discover dedicated solutions and contact us to improve the food safety of your production line:

Sei interessato ai nostri prodotti?

Chiedi ai nostri esperti maggiori informazioni